The Ultimate Guide to Cargo Control & Load Securement

Introduction: Why Proper Load Securement is Non-Negotiable

On every transport mission, whether it's a cross-country haul or simply taking your prized motorcycle to the track, one of the most overlooked steps carries the highest risk: load securement. Proper cargo control is far more than just "tying things down." It's a science—a professional discipline of safety, efficiency, and regulation.

Statistics show that thousands of traffic accidents each year are directly caused by cargo shifting or falling from vehicles during transit. These incidents not only result in millions of dollars in damaged goods but can also trigger fatal chain-reaction collisions, posing a massive threat to public safety. Furthermore, non-compliant cargo securement can lead to heavy fines from law enforcement and even result in your vehicle being taken out of service.

Therefore, a professional load securement strategy isn't a cost; it's an investment. It protects not only your cargo but also your brand's reputation, your legal compliance, and the life of every person on the road. This guide will provide a deep dive into the core principles of cargo control, helping you choose the most reliable and efficient solution for every transport task.

The Core Principles: WLL vs. Breaking Strength

Before we get into equipment, we must understand the two most critical concepts in the world of cargo control: Working Load Limit (WLL) and Breaking Strength (BS). Confusing these two is the most common and dangerous mistake in the industry.

- Breaking Strength (BS): This is the maximum force a new strap or piece of hardware can withstand under laboratory conditions before it fails. It is a point of failure and should never be used as a guideline for actual work.

- Working Load Limit (WLL): This is the maximum load a tie-down should be subjected to during normal, everyday use. The WLL is typically set at one-third (1/3) of the Breaking Strength, providing a 3:1 safety factor. At all times, the combined WLL of your tie-down system must be equal to at least 50% of the weight of the cargo you are securing. This is the golden rule you must follow.

Using the WLL as your only reference point is the first step to ensuring safety. At Xiangle, all of our products are clearly marked with their WLL to ensure you can make the safest choice.

The Complete Arsenal: Types of Cargo Control Equipment

Depending on the cargo type and transport scenario, there are many specialized types of securement equipment. Understanding their unique characteristics is fundamental to making the right choice.

Motorcycle & UTV Tie-Down Systems: Securing Your Passion

For powersports vehicles like motorcycles, UTVs, and ATVs, standard tie-down straps are not enough. You need a specialized system designed to protect the vehicle's bodywork and accommodate complex anchor points. These systems often include straps with integrated Soft Loops to prevent scratching paint and chrome, as well as special hardware designed for handlebars or wheels.

As specialists in the powersports tie-down field, we understand the importance of every detail.

Read our Ultimate Guide to Tying Down a Motorcycle & UTV to learn how to secure your ride like a pro.

Retractable Ratchet Straps: The Future of Tie-Downs

Imagine a world with no more tangled, messy webbing to manage; no more struggling to pull and store excess strap length in tight spaces. That is the revolutionary experience delivered by our self-retracting ratchet straps. With the simple push of a button, excess webbing is automatically retracted, increasing the efficiency of your tie-down and release process by over 50%.

Our technology, built with a robust, internal coiling spring and a smooth, jam-free retraction system for long-lasting, reliable performance, offers you unprecedented convenience and reliability.

Explore the Revolution: A Guide to Retractable Ratchet Straps and see how this technology will change the way you work

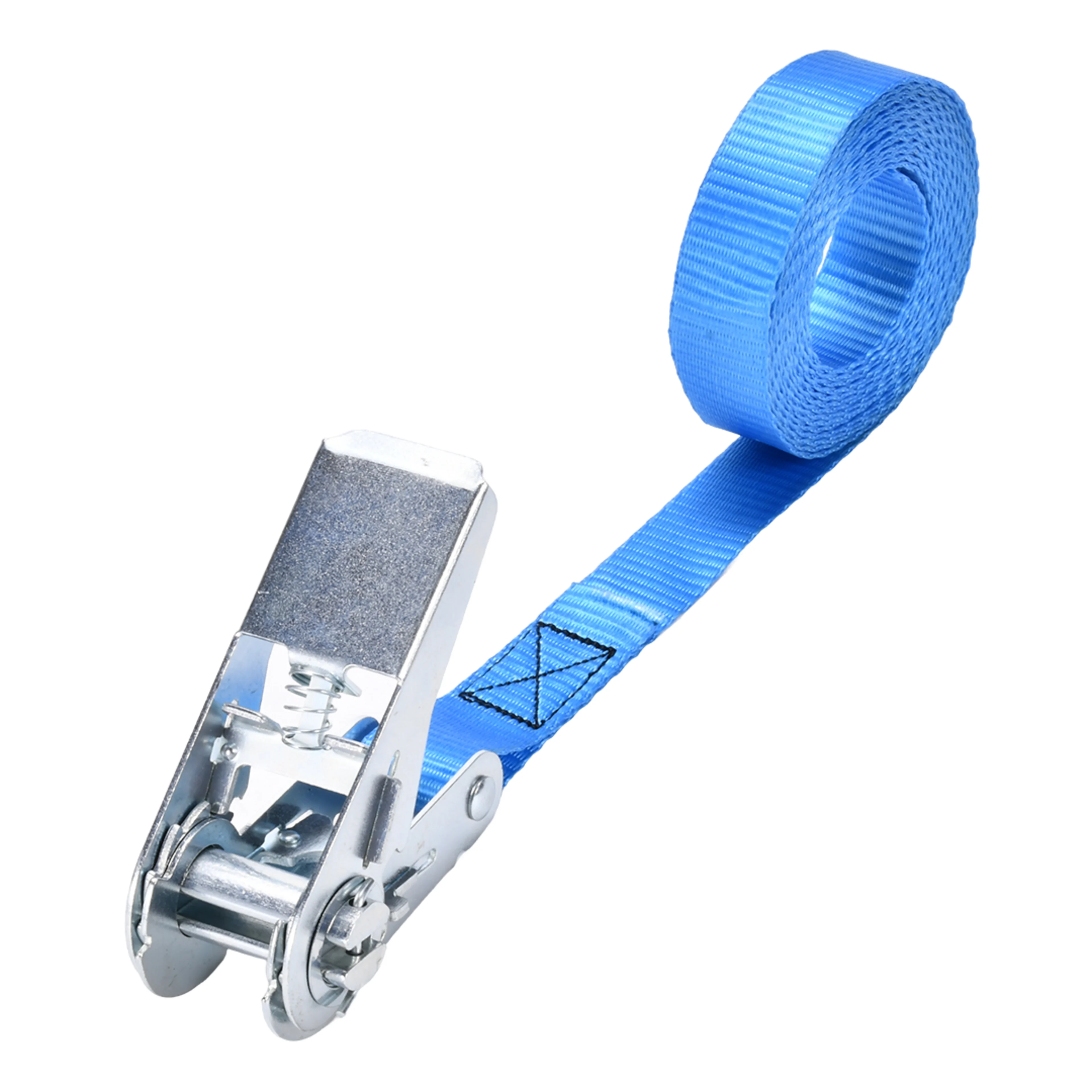

Ratchet Straps: The Versatile Workhorse for Any Load

The ratchet strap is the most widely used tool in the cargo control industry. Its mechanical ratchet assembly allows you to apply significant, controlled tension to your cargo, ensuring it remains stable throughout the entire journey. From tying down furniture and securing equipment to professional logistics, the ratchet strap is an indispensable choice.

They are available in a wide range of sizes and strength ratings, from light-duty 1-inch straps to heavy-duty 4-inch straps, to meet the demands of nearly any application.

Master the Basics with our Complete Guide to Ratchet Straps and learn everything from selection to operation.*

Cam Buckle Straps: For Delicate and Secure Loads

When you are transporting items with sensitive surfaces—like the chrome exhaust pipes on a motorcycle, antique furniture, or glass panels—over-tightening can cause damage. This is where the cam buckle strap excels. It operates with a spring-loaded cam buckle that secures the webbing, allowing you to hand-tighten the strap to the perfect tension—firm enough to secure, but never enough to crush.

Learn When to Choose Cam Buckle Straps by reading our detailed guide.

Webbing, Hardware, and Custom Solutions

For many brands and large distributors, having a product that reflects their brand identity and meets specific technical requirements is crucial. As a direct manufacturer, we offer comprehensive OEM/ODM services. You can select the webbing's color, material, and strength, print your logo directly onto it, and pair it with your choice of hardware.

Our robust supply chain and over 15 years of manufacturing expertise ensure that we can turn your precise vision into a high-quality product.

Start Your Brand Journey with our Guide to Custom Straps, Webbing & Hardware How to Choose the Right Tie Down for Your Load

Faced with many options, following these simple steps will help you make a quick and informed decision:

1. Assess the Cargo: What is its weight, size, shape, and does it have any fragile surfaces?

2. Define the Scenario: Are you transporting it in an enclosed van, on an open flatbed, or in a small pickup truck?

3. Calculate the WLL: Ensure the combined WLL of all your tie-downs is at least half the weight of your cargo.

4. Select the Type: For heavy loads requiring high tension, choose ratchet straps. For fragile items, choose cam buckle straps. For specialized cargo like motorcycles, use a dedicated system.

5. Check the Fittings: Make sure the end-fittings (hooks) on your straps are compatible with the anchor points on your vehicle.

Key Industry Regulations You Must Know

In markets like North America, the Department of Transportation (DOT) and the Federal Motor Carrier Safety Administration (FMCSA) have strict legal requirements for cargo securement. While the regulations are complex, the core requirements include:

- The cargo securement system must be able to withstand specific g-forces in all directions (e.g., 0.8g forward, 0.5g rearward and sideways).

- Tie-down equipment must be clearly marked with its Working Load Limit (WLL).

- The use of any damaged, worn, or knotted tie-downs is prohibited.

As a responsible manufacturer, all Xiangle products are built in strict accordance with international standards to help our clients meet these regulations.

Partner with Xiangle: Your Custom Cargo Control Manufacturer

For over 15 years, Xiangle has been dedicated to providing the most reliable and innovative cargo control products to a global clientele. We are more than just a manufacturer; we are your trusted partner.

- Direct-from-Factory Advantage: We have mastery over the entire production chain, from webbing extrusion to hardware stamping, ensuring superior quality and competitive pricing.

- Pioneering R&D: Our self-developed retractable ratchet straps are leading a change in the industry.

- Comprehensive Customization: We can provide full OEM/ODM services to meet your needs, from logo printing to custom packaging design.

- International Standards: Our products adhere to top international certifications like TUV/GS, REACH and are sold in major markets worldwide, including North America, Europe, Australia, etc.

Whether you need a reliable manufacturing partner for your brand or a more efficient solution for your transport business, we have the capabilities to meet your needs.

Related Products

Related Blogs

GET IN TOUCH WITH YOUR DEDICATED TEAM

Email: [email protected]

ABOUT XIANGLE RATCHET STRAP

Founded in 2006, Xiangle Ratchet Strap is a specialized manufacturer of cargo tie-down solutions, focusing exclusively on tie-down products for transportation and logistics. With nearly two decades of industry experience, we offer reliable OEM & ODM services, tailored to meet the unique requirements of our global B2B clients. Backed by consistent quality, fast lead times, and responsive service, Xiangle is your trusted partner for high-performance cargo securing solutions.