A Complete Guide to Ratchet Straps: Everything You Need to Know

From securing heavy machinery on a flatbed trailer to tying down your motorcycle for a weekend trip, ratchet straps are the indispensable tool for safe and reliable cargo securement. But not all tie down straps are created equal, and understanding how to use ratchet straps correctly is critical for safety and preventing damage.

Welcome to the definitive guide on ratchet straps, brought to you by the experts at XiangleRatchetStrap. As a leading factory and manufacturer of cargo control solutions, we specialize in producing high-quality ratchet straps and offer extensive OEM/customization services. In this guide, we'll share our deep industry knowledge to help you choose, use, and maintain your straps like a professional.

What Are Ratchet Straps and How Do They Work? (The Mechanics of Tension)

At its core, a ratchet strap is a two-part tie-down system designed to apply and maintain tension on cargo.

- The Fixed End: This is the shorter piece, consisting of the ratchet mechanism itself, a short length of webbing, and an end fitting (like a hook).

- The Adjustable End: This is the long length of webbing with an end fitting attached.

The magic happens in the ratchet mechanism:

The loose end of the webbing is threaded through a rotating spool in the ratchet, called a mandrel. By cranking the handle up and down, a set of gears and pawls (locking levers) grips the gear teeth, allowing the mandrel to turn in only one direction. This winds the webbing, applying immense mechanical force and tension to the strap. Once tensioned, the pawls lock the mechanism, ensuring your cargo remains secure.

A Tip From Our Factory Floor: The Importance of the Mandrel

As manufacturers, we know the heart of a ratchet's longevity is the mandrel. A poorly made mandrel with sharp or rough edges will slowly shred your webbing from the inside out with every use. That's why we insist on using perfectly smooth, polished steel mandrels in our mechanisms. This small detail, often overlooked, significantly extends the service life of the entire strap—a mark of true factory quality.

Choosing the Right Ratchet Strap: A Breakdown by Size and Strength

Selecting the right strap is the most important step. The key metric you need to know is the Working Load Limit (WLL). The ratchet strap WLL is the maximum load a strap is certified to handle safely during normal use. It is typically one-third of the strap's Breaking Strength (BS). Always base your choice on the WLL, not the Breaking Strength.

1-Inch Straps: For Light-Duty and Powersports Applications

1-inch ratchet straps are perfect for lighter, more sensitive loads. Their lower WLL and smaller size make them ideal for preventing damage from over-tensioning.

- Common Uses: Securing motorcycles, ATVs, dirt bikes, furniture, appliances, and bundling light materials.

- Xiangle Advantage: As a manufacturer, we can produce 1-inch straps in custom colors and with your company logo printed on the webbing, making them perfect for branded powersports kits or retail products.

2-Inch Straps: The Most Versatile and Popular Choice

2-inch ratchet straps are the workhorses of the cargo control world. They offer a perfect balance of strength and usability for a vast range of applications.

- Common Uses: Car hauling, securing general freight in trucks and trailers, tying down mid-size equipment, and agricultural use.

- Xiangle Advantage: This is our specialty. We factory-produce millions of feet of high-tenacity Polyester (PES) webbing for our 2-inch straps, ensuring maximum durability and weather resistance. We offer full customization on length, color, and end fittings.

3-Inch & 4-Inch Straps: For Heavy-Duty and Industrial Loads

When you need to secure serious weight, heavy duty ratchet straps are the only choice. These 3-inch and 4-inch straps are engineered for the most demanding industrial and transport applications.

- Common Uses: Securing heavy machinery on flatbed trailers, tying down construction materials like steel beams and concrete, and securing loads in intermodal containers.

- Xiangle Advantage: Our heavy-duty straps are a testament to our manufacturing capabilities. They are rigorously tested to meet or exceed DOT and WSTDA standards, ensuring your most valuable and heaviest loads are secure.

A Visual Guide to End Fittings (Hooks & Anchors)

The end fitting is your connection to the anchor point. Choosing the right one from the various types of ratchet straps is crucial for a secure system.

S-Hooks (Vinyl Coated and Standard)

Typically found on lighter-duty straps (like 1-inch), S-hooks are easy to use. The vinyl-coated version is popular for powersports as it prevents scratching painted or chrome surfaces.

J-Hooks and Grab Hooks

Also known as double J-hooks, these are versatile and strong, designed to securely latch onto D-rings, O-rings, and trailer side rails. Grab hooks are specifically designed to connect to chain links.

Flat Hooks

These are the standard for the flatbed trucking industry. They are designed to fit perfectly over the side rails (rub rails) of a flatbed trailer, providing a secure and stable connection.

E-Track & L-Track Fittings

These specialized fittings are designed for logistic track systems installed inside enclosed trailers, vans, and box trucks. They offer incredible versatility, allowing for anchor points to be placed exactly where they are needed.

Soft Loops for Scratch-Free Securing

While not a hook, a soft loop is an essential accessory. It's a short strap that wraps around a sensitive part of your cargo, like handlebars or a painted frame. You then attach the metal hook of your ratchet strap to the soft loop, ensuring no metal ever touches and damages your cargo. As an OEM manufacturer, we can bundle custom soft loops with any strap order.

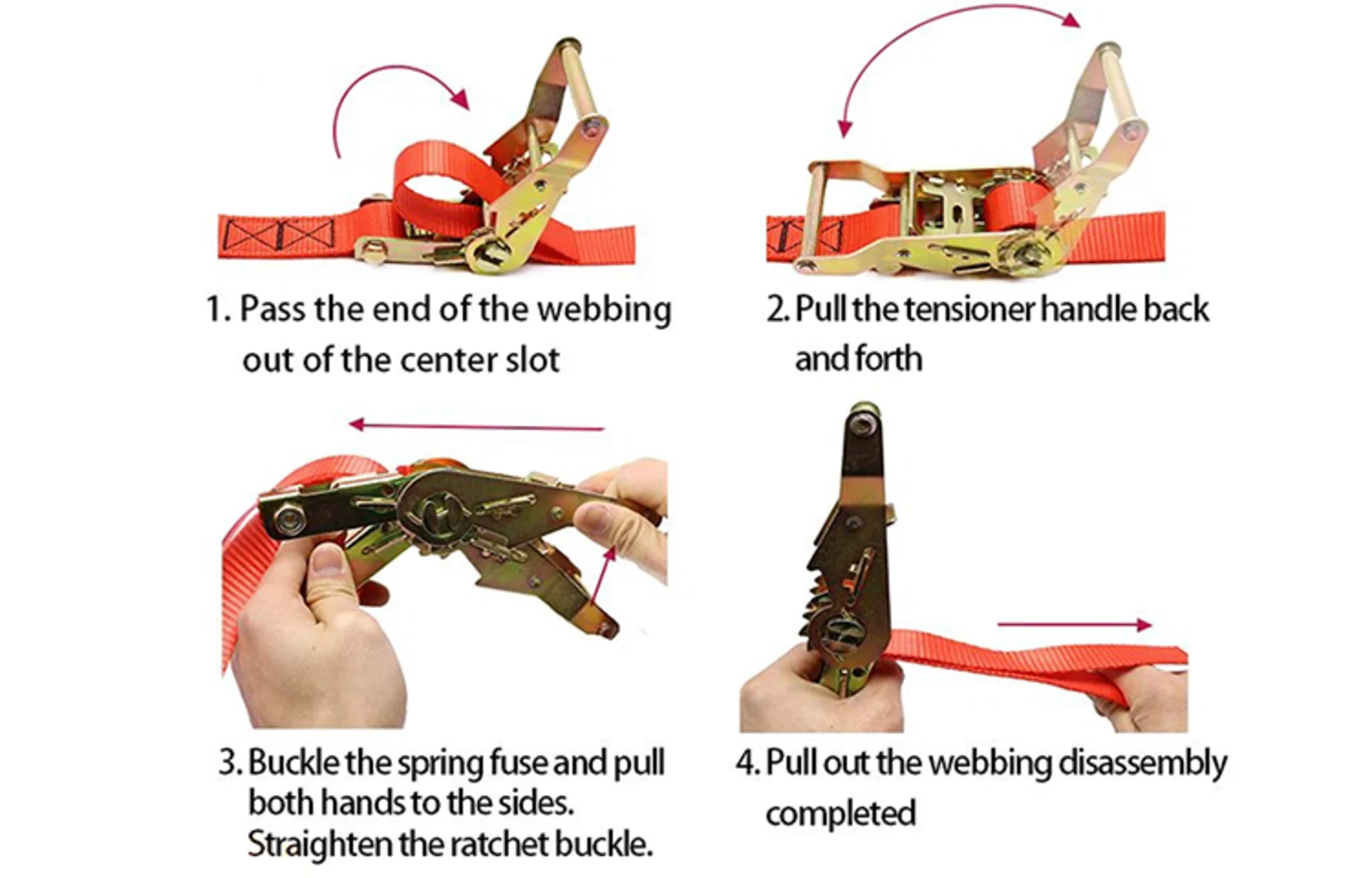

Step-by-Step Instructions: How to Use, Tighten, and Release a Ratchet Strap

To Tighten:

- Open the Ratchet: Pull the release catch on the top handle assembly to open the ratchet so it lies flat.

- Thread the Webbing: Feed the loose end of the webbing from the bottom, up through the slot in the mandrel, and pull all the excess slack through.

- Start Tensioning: Crank the handle back and forth. You will feel and hear the mechanism clicking as it tightens the webbing.

- Lock It: Once you've reached the desired tension, close the handle completely. It is now locked.

To Release:

- Pull the Release Catch: Pull and hold the release catch to disengage the locking pawls.

- Open Fully: Open the ratchet handle 180 degrees until it is completely flat. The mechanism will release its tension with a "pop."

- Pull Webbing Free: With the ratchet fully open, you can now easily pull the webbing out of the mandrel.

Safety is Paramount: Common Mistakes and How to Avoid Them

- Using Underrated Straps: Never use a strap whose WLL is less than the item you are securing. Always use an appropriate number of straps to meet or exceed the cargo weight.

- Ignoring Sharp Edges: Webbing pulled tightly over a sharp metal or concrete edge can be cut easily. Always use corner protectors to shield the webbing.

- Using Damaged Straps: A frayed or cut strap is a failed strap waiting to happen. Inspect every strap before every use.

- Using for Lifting: Ratchet straps are for lashing and tying down only. NEVER use them for lifting or suspending loads. They are not designed for this purpose and it is extremely dangerous.

Inspection and Maintenance: How to Know When to Retire a Strap

According to WSTDA guidelines, a strap must be immediately removed from service if any of the following are visible:

- Holes, tears, cuts, or snags in the webbing.

- Broken or worn stitching in the load-bearing splices.

- Evidence of melting, charring, or chemical damage.

- Knots in any part of the webbing.

- Bent, cracked, pitted, or corroded hardware.

- The WLL identification tag is missing or unreadable.

Frequently Asked Questions (FAQ)

Q: What's the difference between WLL and Breaking Strength?

A: Working Load Limit (WLL) is the maximum force a strap should EVER be subjected to in normal use. Breaking Strength (BS) is the force at which a new strap will fail in testing. WLL is typically 1/3 of the BS, providing a critical safety factor. Always secure your cargo based on the WLL.

Q: How many tie-down straps do I legally need?

A: This depends on your cargo's weight, length, and local DOT regulations. A general rule of thumb from the FMCSA is to use one strap for every 10 feet of cargo, and at least two straps for any cargo, regardless of length. Always consult the official regulations for your specific load.

Q: Why is my ratchet strap hard to release?

A: This usually happens when the mandrel is over-spooled with too much webbing, causing it to jam. To prevent this, when you first thread the strap, pull as much slack through as possible by hand before you start ratcheting. This minimizes the amount of webbing that winds onto the spool.

Q: Can I get custom-colored or branded ratchet straps?

A: Absolutely. As a direct manufacturer, we offer full OEM/customization services. This is one of our key advantages. We can produce straps in your brand colors, print your logo on the webbing, and create custom lengths and assemblies.

Find Wholesale & Custom Ratchet Straps at Xiangle

Choosing the right ratchet strap supplier is as important as choosing the right strap. By working directly with XiangleRatchetStrap, you are partnering with the factory.

We offer:

Wholesale & Factory-Direct Pricing: Get the best value by cutting out the middleman.

Full OEM & Customization: We can manufacture straps to your exact specifications. This includes:

- Custom webbing colors.

- Your company logo printed directly on the strap.

- Any length you require.

- A wide variety of hardware and end fittings.

- Bulk packaging solutions.

Whether you need a full container of heavy duty ratchet straps for your transport fleet or a custom-branded tie-down kit for your retail product, we have the manufacturing expertise to deliver.

Contact our team today to get a quote and discuss your wholesale or custom ratchet strap needs.

GET IN TOUCH WITH YOUR DEDICATED TEAM

Email: [email protected]

ABOUT XIANGLE RATCHET STRAP

Founded in 2006, Xiangle Ratchet Strap is a specialized manufacturer of cargo tie-down solutions, focusing exclusively on tie-down products for transportation and logistics. With nearly two decades of industry experience, we offer reliable OEM & ODM services, tailored to meet the unique requirements of our global B2B clients. Backed by consistent quality, fast lead times, and responsive service, Xiangle is your trusted partner for high-performance cargo securing solutions.