Global Cargo Securing Calculator

Professional cargo securing calculator supporting North America (DOT) and Europe/Australia (EN 12195-1/AS/NZS 4380) standards. Choose your region for automatic unit selection and calculation standards.

Select Your Region

Choose your region to see the appropriate cargo securing calculator and standards

North America

- DOT compliance for US and Canada

- WLL (Working Load Limit) calculations

- Imperial units (lbs, ft)

- DOT tie-down requirements

- Commercial vehicle regulations

Europe & Australia

- EN 12195-1 (Europe) compliance

- AS/NZS 4380 (Australia) compliance

- Metric units (kg, m)

- STF/LC calculations

- Indirect and direct lashing

Select Securing Method

Choose the method for securing your cargo

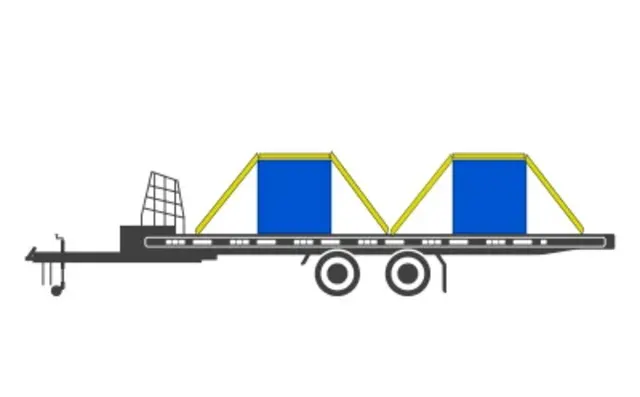

Indirect Tie-Down

Straps go over the top of the cargo

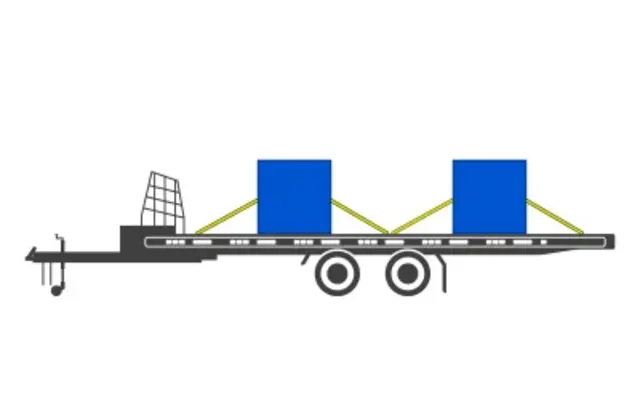

Direct Tie-Down

Straps directly connect cargo to vehicle

How it works

The calculator will determine how many straps of your selected WLL rating are needed to safely secure your cargo according to North America (DOT) standards.

Mastering North American Cargo Securement: A Guide to FMCSA & NSC Rules

Navigating the complexities of cargo securement regulations in North America can be challenging. Governed by the Federal Motor Carrier Safety Administration (FMCSA) in the United States and Canada's National Safety Code (NSC) Standard 10, these rules are built on a foundation of performance standards designed to withstand real-world forces.

Core Principles of North American Cargo Securement

The core principle of the North American system is that your cargo securement must be strong enough to resist 0.8g of forward force (hard braking), 0.5g of rearward force (acceleration), and 0.5g of sideways force (turning). To simplify these physics, the regulations provide two parallel, mandatory pillars for compliance:

Pillar 1: Aggregate Working Load Limit (AWLL)

The total strength of your securement system must be at least 50% of your cargo's total weight.

Pillar 2: Minimum Number of Tie-Downs

You must use a minimum number of straps based on the cargo's length and positioning.

Pillar 1: Calculating Your Aggregate Working Load Limit (AWLL)

The fundamental rule is that the total strength of your securement system (the AWLL) must be at least 50% of your cargo's total weight. However, calculating the AWLL isn't as simple as adding up the Working Load Limits (WLL) of your straps. The contribution of each tie-down depends on how it's used:

Direct Tie-Downs

Each strap attached directly from the vehicle to the cargo contributes 100% of its WLL to the AWLL. This method is common for heavy machinery with dedicated attachment points.

Formula: Direct Tie-Down Contribution = 50% × WLL

Indirect Tie-Downs (Cross-Vehicle)

Straps that go over or around the cargo and anchor to opposite sides of the vehicle contribute 100% of their WLL. This is the most common method for palletized goods or lumber.

Formula: Cross-Vehicle Contribution = 100% × WLL

Indirect Tie-Downs (Same Side)

If a strap goes around the cargo but anchors back to the same side of the vehicle, it only contributes 50% of its WLL. This is a critical and often overlooked detail that can lead to non-compliance.

Formula: Same-Side Contribution = 50% × WLL

Pillar 2: Meeting the Minimum Tie-Down Count

Independently of the AWLL strength calculation, you must also use a minimum number of straps based on the cargo's length and how it's positioned. For cargo not blocked by a headboard or bulkhead:

Tie-Down

For articles ≤ 5 feet in length and ≤ 1,100 lbs.

Tie-Downs

For articles ≤ 5 feet but over 1,100 lbs, or for any article between 5 and 10 feet long, regardless of weight.

Tie-Downs

For articles longer than 10 feet, you need 2 tie-downs for the first 10 feet, plus one additional tie-down for every 10 feet (or portion thereof) after that.

Critical

Don't guess on safety. These dual requirements make manual calculation complex and prone to error.

Frequently Asked Questions

Common questions about DOT cargo securing standards and North American compliance requirements

How many tie down straps do I need for 20 feet cargo?

According to DOT standards (US), you need at least 3 tie-downs for cargo over 20 feet (6.1m). For cargo under 20 feet, minimum 2 tie-downs are required. Additional tie-downs may be needed based on cargo weight and securing method.

What is WLL in cargo securement?

WLL (Working Load Limit) is the maximum safe working load that a tie-down strap can handle according to DOT standards. It's used to calculate the required number of tie-downs and ensure cargo weight is properly distributed across securing equipment.

What are the main DOT cargo securement requirements?

DOT requirements include: aggregate WLL ≥ 50% of cargo weight for indirect securement, direct tie-downs contribute 100% of their WLL, minimum tie-downs based on cargo length, and compliance with commercial vehicle regulations.

How do I calculate tie down requirements for DOT compliance?

Use our North America calculator by selecting your region, entering cargo weight, dimensions, securing method (direct/indirect), and tie-down angle. The tool automatically calculates required WLL and recommends appropriate tie-down configurations based on DOT standards.

What's the difference between direct and indirect tie-downs in DOT standards?

Direct tie-downs connect cargo attachment points directly to the vehicle, providing 100% efficiency. Indirect tie-downs go over the top of cargo and require aggregate WLL ≥ 50% of cargo weight under DOT regulations.

What safety margin should I use for DOT cargo securement?

DOT standards require minimum 20% safety margin for cargo securement. This ensures adequate capacity to handle dynamic loads during transportation and provides a buffer for unexpected conditions.

Are there different requirements for different cargo types under DOT?

Yes, DOT has specific requirements for different cargo types. Heavy machinery often requires direct tie-downs, while general cargo can use indirect methods. Always ensure compliance with DOT regulations for your specific cargo.

How does DOT ensure commercial vehicle safety?

DOT ensures commercial vehicle safety through comprehensive regulations covering cargo securement, vehicle maintenance, driver qualifications, and regular inspections. Compliance is enforced by state and federal authorities.

Which units should I use for DOT calculations?

DOT standards use imperial units: weight in pounds (lbs), dimensions in feet (ft). Our calculator automatically applies the correct units for North American compliance.

How often should I verify my DOT cargo securing calculations?

Verify calculations whenever cargo characteristics change (weight, dimensions, type) or when transporting to different states. Regular verification ensures continued DOT compliance and safety.

Need More Help?

Our DOT-compliant cargo securing calculator is designed to be comprehensive and user-friendly, but cargo securing can be complex. Always consult with qualified professionals for critical applications or when in doubt.