25mm 316 Stainless Steel Cam Buckle - 450kg Breaking Strength

Tailored Business Programmes

Partner with UsQuestions? Need it custom?

We can help!Specifications

| Minimum Breaking Strength: 450 kg | Lashing Capacity: 225 daN |

| Width: 25mm | Material: Stainless Steel |

| Finish: Polished | Compliance: EN 12195-2 |

| Grade: 316 Stainless | Product Weight: 71 g |

Description

Ultimate Corrosion Resistance: The 316 Stainless Steel Cam Buckle

When your application demands the absolute best in corrosion resistance, our 25mm 316 Stainless Steel Cam Buckle is the only choice. Forged from marine-grade 316 stainless steel, this buckle is specifically designed to withstand the harshest environments, including constant saltwater exposure and industrial chemicals. Its superior material composition prevents pitting and corrosion, ensuring your EN 12195-2 compliant lashing systems remain safe and operational for years.

Engineered for No-Compromise Marine & Industrial Use

- Marine & Sailing: The premier choice for creating boat cover straps, sail ties, and securing gear on any watercraft in saltwater environments.

- Chemical & Specialist Transport: Ideal for straps used in chemical transport, or any area with corrosive agents.

- All-Weather Commercial Use: Perfect for any outdoor application in coastal regions where road salt or sea spray can degrade standard hardware.

Your Factory Partner for Elite Components

As a specialist China manufacturer, we build the elite components that define a superior product.

- Marine-Grade 316 Stainless Steel: We use certified 316 SS to guarantee the ultimate protection against pitting and crevice corrosion, offering a significant upgrade over 304 SS.

- Damage-Free Tensioning: The smooth cam buckle mechanism allows for hand-tight tensioning, protecting fragile and valuable cargo from crushing damage.

- Complete OEM Assemblies: Partner with our factory to create a complete, no-compromise marine-grade lashing assembly with custom webbing.

Build a lashing system that will never surrender to the elements. Contact us to discuss your custom OEM project!

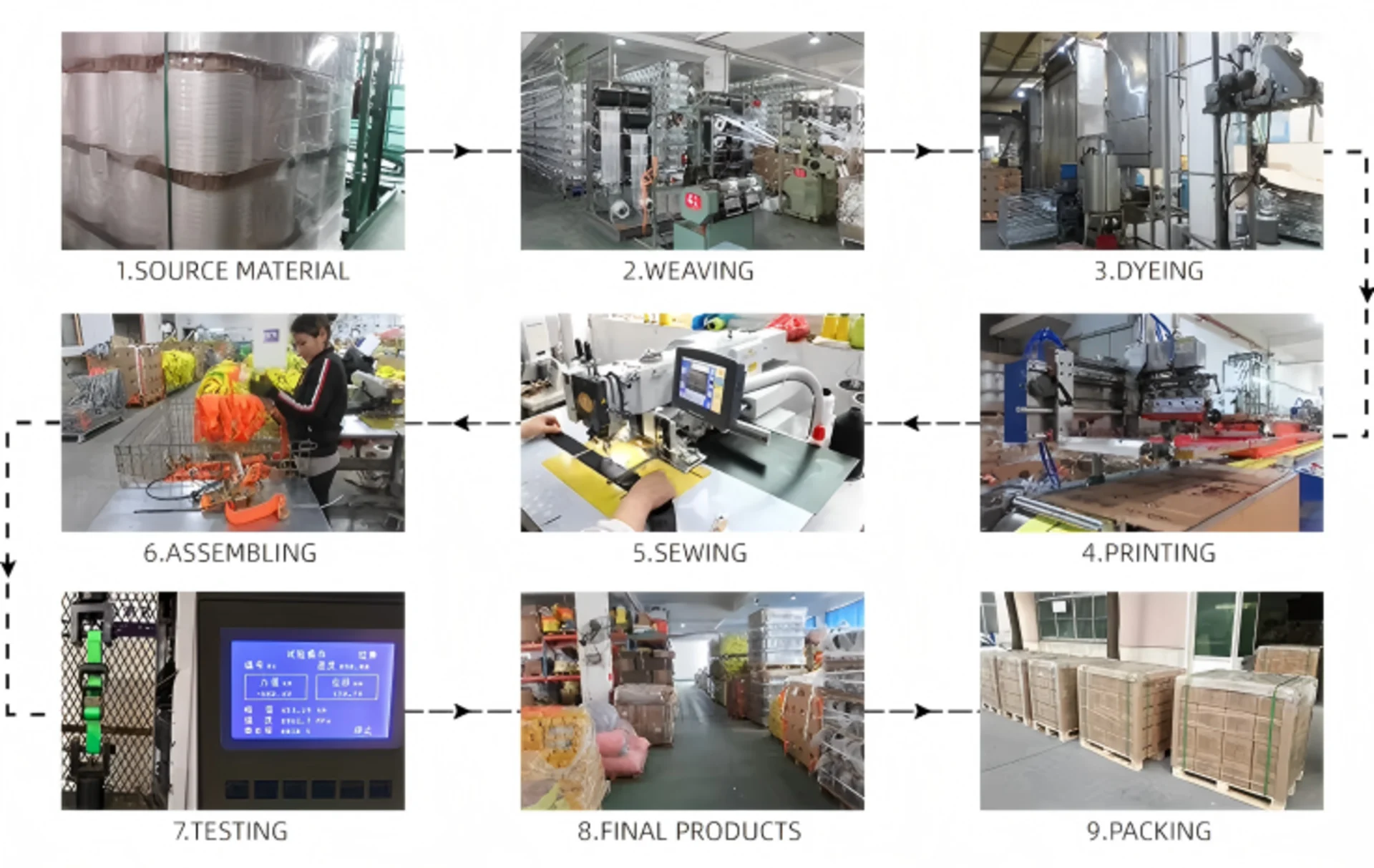

Our Manufacturing Process

Explore our production capabilities and advanced manufacturing processes that ensure consistent quality and reliability in every ratchet strap we produce.

FREQUENTLY ASKED QUESTIONS:

Yes. As a factory, we specialise in OEM/ODM services. We can produce custom logos, colours, hardware, and packaging for your private label products. Contact us with your specifications to begin.

For our standard, in-stock products, our MOQ is just 1 piece. For bespoke orders, the MOQ varies with complexity. We hold stock of raw materials to enable flexible ordering.

Yes, we offer competitive tiered pricing for bulk orders. To receive a fast quotation, simply provide us with the product model, quantity, and destination port.

Our lead time is exceptionally quick. For standard products, we guarantee dispatch within 7 days for orders up to 5,000 units. For custom orders, the lead time will be confirmed against your specific requirements.

We provide free samples for all standard products; you only need to cover the cost of shipping. For custom samples, please speak with our sales team to discuss your project.

Our standard terms are a 30% T/T deposit to commence production, with the 70% balance payable in full before the goods are dispatched from our factory.

Yes, we provide full bespoke packaging solutions. For retail environments, we can supply clamshells, branded sleeves, and point-of-sale display boxes. For industrial needs, we pack in bulk using robust export cartons on pallets.

We utilise 100% high-tenacity, industrial-grade polyester (PES) webbing with a low elongation factor (<7%). This material is naturally resistant to UV degradation, which ensures maximum durability for outdoor applications.

Our products are engineered to meet or surpass key international standards, including TUV GS for the European market and WSTDA for North America. Copies of all compliance certificates can be supplied with your order.

Yes, we are the direct manufacturer. We welcome factory audits from clients or their appointed third-party inspection agencies (e.g., SGS, Intertek) and can facilitate virtual factory tours.